As the European Union prepares to roll out the Digital Product Passport (DPP) from 2027, global apparel sourcing is on the brink of one of the most significant regulatory shifts in decades. The DPP will require every product entering the EU market to carry a digital identifier—allowing consumers and regulators to trace materials, processes, and supply chain partners with unprecedented clarity.

For Bangladesh, the world’s second-largest apparel exporter, this transition presents both uncertainty and opportunity. While the concept is new and the roadmap is still evolving, the implications reach far beyond compliance: it demands a supply chain that is transparent, interoperable, and digitally connected from fiber to finished garment.

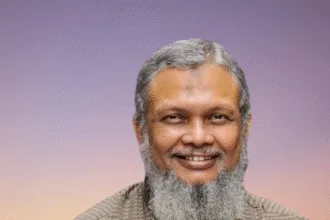

To understand the industry’s current level of preparedness and the bigger strategic picture, Fashion Business Journal (FBJ) spoke with Md. Fazlul Hoque, Managing Director of Plummy Fashions Ltd.—a global leader in sustainable knitwear and one of the world’s highest-rated LEED Platinum green factories. With decades of leadership experience, including serving as President of BKMEA, Hoque offers an unfiltered and practical perspective on what lies ahead for Bangladesh.

FBJ: How prepared is Bangladesh’s apparel industry to adopt the EU-mandated Digital Product Passport system, and what steps are being taken to ensure compliance across the entire supply chain?

Md. Fazlul Hoque: To be honest, the Digital Product Passport is still a completely new idea for our industry—especially for Bangladeshi exporters. The EU is planning to implement it from early 2027, and initially even I wasn’t fully clear about what exactly they wanted or how it would work. But now the broad objective is clearer: every product will carry a QR code, allowing any retail customer or stakeholder to track the entire supply chain. From yarn and fabric to dyes, chemicals, trims, accessories—everything will be traceable.

The intention is straightforward: they want a fully transparent and compliant supply chain. Conceptually, it’s fantastic.

Also Read: The DPP Shift: Is Bangladesh Ready?

But if you ask whether Bangladesh is prepared right now, I would say not fully. We are aware of the coming change, but readiness will take time. A few factories have started pilot projects; industry associations are trying to educate exporters. That is where we stand today.

There are some early concerns. One major question is whether the DPP rules will be implemented equally across all sourcing countries. From past experience, we often find that certain regulations are enforced more strictly on Bangladesh than on others.

Another issue is whether compliance will be mandatory for every single exporter. If yes, smaller factories—and the small importers who depend on them—will face serious challenges. I can ensure compliance within my own factory, but ensuring full compliance across the entire supply chain, including small-scale accessory makers, dye houses, printers, embroiderers—that is far more difficult.

This could also increase costs. In fact, the toughest burden may fall on smaller suppliers who support the export industry. They will need significant investments to meet EU expectations.

So yes, a challenging time is ahead—not only for garment manufacturers but for the entire ecosystem.

FBJ: Do you see the Digital Product Passport as merely a compliance requirement or as an opportunity for Bangladesh to reposition itself as a transparent, high-value sourcing destination in the next decade?

Md. Fazlul Haque: I believe every challenge brings an opportunity. The DPP may feel like pressure now, but if we respond quickly, efficiently, and collectively, it can actually help Bangladesh reposition itself.

Also Read: Reuse Is Ready: Fashion’s Missed Opportunity

If we can make the whole supply chain transparent, digital, and fully compliant, then it becomes a major selling point. It’s not just about meeting a regulation—it’s about proving that Bangladesh is a high-value, trustworthy, sustainable sourcing destination.

But this won’t happen on its own. It requires serious commitment from everyone, not just garment factories. Yarn suppliers, mills, dyeing units, chemical suppliers, accessory makers, printers, embroiderers—every link in the chain has to upgrade.

If we can align these efforts and respond proactively, then the Digital Product Passport becomes more than compliance—it becomes a source of competitive advantage. It can help Bangladesh stand out globally for transparency, responsibility, and sustainability.