OEKO-TEX has selected TextileGenesis, a Lectra company, to digitise transaction certificates for its ORGANIC COTTON certification, marking a significant step toward strengthening traceability and fraud prevention across global cotton supply chains.

The move comes as organic cotton gains strategic importance for brands, regulators, and consumers seeking credible sustainability claims. OEKO-TEX reported a 381% year-on-year increase in ORGANIC COTTON certifications by the end of December 2025, underscoring the rapid growth of the market and the rising risk of mislabelled or unverifiable material flows.

As volumes expand, the industry’s long-standing reliance on paper-based transaction certificates has increasingly been viewed as a weak link. OEKO-TEX said the partnership with TextileGenesis aims to replace fragmented documentation with a secure, digital system that connects physical cotton movements with verified certification data in real time.

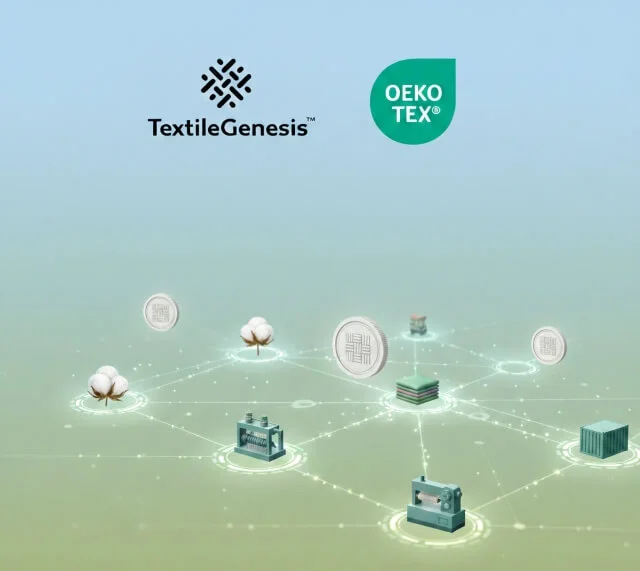

Under the collaboration, TextileGenesis’ token-based Fibercoin™ technology will link every shipment of certified organic cotton to a unique digital token, creating a closed-loop chain of custody from fibre to finished product. The system is designed to make transactions tamper-resistant while reducing administrative burdens for ginners, spinners, manufacturers and brands.

“By using TextileGenesis’ pioneering Fibercoin™ technology, we are creating a digital chain of custody for OEKO-TEX certified organic cotton and eliminating pdf and paper-based transaction certificates,” Amit Gautam, CEO of TextileGenesis, said in a statement. “This collaboration helps ensure that organic cotton claims are easier to manage and verifiable at scale.”

OEKO-TEX said the digitalisation effort builds on its existing in-house GMO testing, which is conducted exclusively within its 17 international testing institutes. Both raw fibre and yarn are tested, allowing organic standards to be verified at the earliest stages of the supply chain and monitored throughout downstream processing.

Dr. Alfred J. Beerli, CEO of OEKO-TEX, said the initiative forms part of a broader digital roadmap aimed at future-proofing certification systems. “Secure, transparent and data-driven processes strengthen the integrity of OEKO-TEX while making certification more efficient and scalable – especially for organic cotton certified by us,” Beerli said.

He added that the digitisation of transaction certificates is intended as a starting point rather than an end in itself. Once fully established, the approach could be extended across other OEKO-TEX certifications and product groups, potentially reshaping how textile compliance is managed at scale.

The partnership follows a pilot project launched in early 2025, which traced selective organic cotton supply chains across India and Bangladesh. The pilot involved ginners, spinning mills, fabric mills and testing institutes, reflecting the complexity of cotton’s multi-tier global supply network.

Between March and August 2025, eleven supply chain actors participated in the trial. According to OEKO-TEX, 24 certificates were added and approved across 19 certified transactions, all of which were successfully captured and validated on the TextileGenesis platform.

Supplier feedback from the pilot indicated strong acceptance of the digital model, particularly in terms of usability and training support. A representative of KKP Spinning Mills Pvt. Ltd. said the shift to digital transaction certificates “is a meaningful step toward better transparency and efficiency,” reducing manual effort while increasing confidence in certified transactions.

Milan Ginning Pressing Limited and Atlas Export Enterprises echoed the sentiment, saying the collaboration had supported better compliance and trust across certified supply chains. For companies operating in high-volume, export-oriented markets such as India and Bangladesh, the system offers a potential pathway to faster audits, lower compliance costs and reduced exposure to fraud-related risks.

The partnership also reflects a broader industry shift toward digital traceability as governments tighten sustainability reporting rules and brands face increasing scrutiny over greenwashing. In Europe, the Corporate Sustainability Reporting Directive (CSRD) and product environmental footprint initiatives are driving demand for verifiable data across supply chains, including fibre origin and processing pathways.

Digital traceability platforms such as TextileGenesis are increasingly positioned as infrastructure for compliance as well as brand assurance, linking certification bodies, suppliers, and brands through shared data systems. By integrating certification workflows directly into digital platforms, OEKO-TEX aims to strengthen the credibility of its standards while improving efficiency for all participants.

TextileGenesis, founded in 2018 and acquired by Lectra, provides software-as-a-service solutions for textile, leather and footwear traceability. Its platform enables fibre-forward traceability for certified and sustainable materials, while also offering supply chain discovery tools for conventional materials. The system identifies and flags compliance and legal risks across supply chains from tier one to tier four.

Lectra, founded in 1973, provides industrial intelligence technology solutions combining software, cutting equipment, data, and services for the fashion, automotive, and furniture industries. The group operates in more than 100 countries and has production sites in France, China, and the United States.

Also read: Reju Selects Rochester for First U.S. Regeneration Hub

Looking ahead, OEKO-TEX and TextileGenesis said they will continue to develop and scale the platform, aiming to expand digital transaction certificates across additional organic cotton supply chains and, eventually, to other certified materials.

“Real-time transparency and interoperability will be essential going forward,” Beerli said. “Our ambition is not only to keep pace with industry developments, but to actively help shape future-ready certification standards.”

As organic cotton continues its rapid growth trajectory, the collaboration signals a shift toward digital-first certification models that aim to safeguard trust in sustainability claims while supporting the global textile industry’s transition to more transparent and resilient supply chains.