The discussion about overproduction in apparel usually focuses on factories. We talk about excess fabric booking, large batch sizes, weak forecasting, and poor controls in cutting and sewing. All of these are real, and we must fix them. But there is another side to the problem that is just as important- the overall demand that brands create and promote. If brands keep pushing more styles, more drops, and more promotions to stimulate sales, the market absorbs more than it needs. Many of these garments are never used enough, and a significant share ends up in landfill, incineration, or in donation streams that are already full. To build a healthy and responsible ready-made garment (RMG) sector, we have to address both sides—how we make and how we sell—so that the total number of garments produced and purchased becomes ‘right sized.’

Fast fashion has trained consumers, especially young people, to buy quickly and often. The promise is simple- the newest look at a very low price. Social media accelerates this cycle with constant trends and micro-seasons. For a teenager or a young adult, the choice feels easy. The item is cheap, the style is hot, and the peer pressure is high. But the long-term effect is waste. Many purchases are worn only a few times. Closets fill up. The thrill fades fast. What felt like a bargain at the counter becomes clutter at home and a burden for the environment. When this pattern repeats across millions of shoppers, the industry must produce far more than society actually needs. The result is overproduction upstream and overconsumption downstream, feeding each other in a loop.

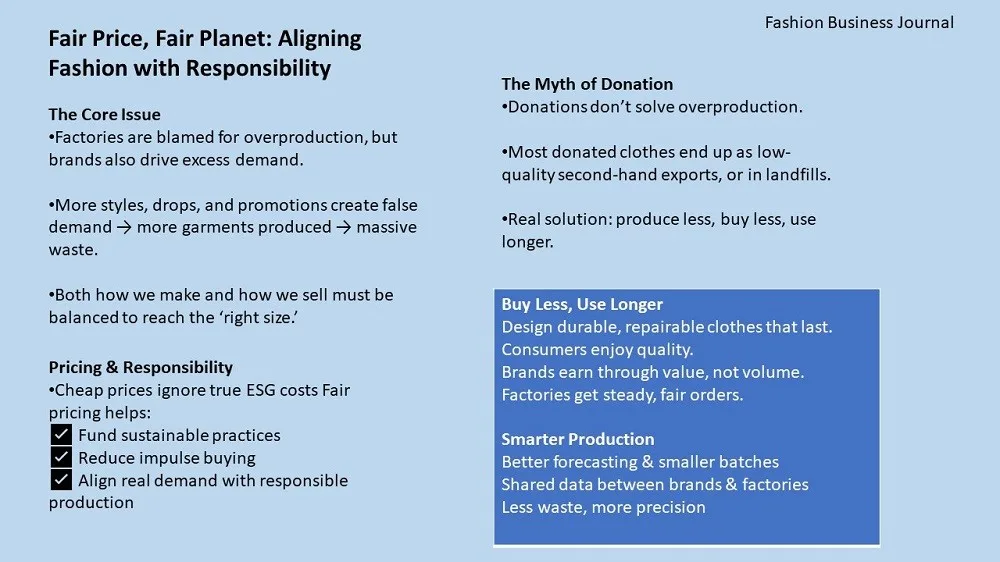

Some argue that donation solves the problem. In practice, donation is not a magic exit. Charities receive more clothing than they can place. A large share still moves to low-income markets as second-hand bales, overwhelming local systems and creating quality and waste issues in those regions. Landfill and open dumping remain common endpoints. The true solution is to prevent excess in the first place—by aligning production with realistic demand and by shaping demand so that people buy less, buy better, and use longer.

Price is a powerful signal for shaping demand. Today, many prices do not fully reflect the cost of responsible production. When environmental, social, and governance (ESG) costs are not properly included—such as living wages, safe workplaces, wastewater treatment, carbon reduction, and proper waste management—the shelf price becomes artificially low. Low prices tempt consumers to buy more than they need. If products carried a fair price that included these real costs, two good things would happen. First, the extra margin would fund the ESG practices we want—cleaner processes, safer factories, longer-lasting garments. Second, the higher but fair price would slow impulse buying. People with the capacity to purchase would pause and think: Do I truly need this item? Will I wear it often? That pause is healthy. It reduces unnecessary demand and helps orders come in the right size.

Also Read: Fair Price — The Missing Link in Bangladesh’s Garment Success Story

This does not mean closing the door on access or style. It means resetting the balance. When a T-shirt or a pair of trousers is made to last, with better fabric, stronger stitching, and a design that stays relevant for more than a few weeks, the value per wear goes up. Consumers still get quality and satisfaction, but they buy less often. Brands still earn, but through value rather than volume. Factories still run, but with steadier orders and better prices that reflect real quality and compliance. In this model, growth comes from durability, services, and loyalty—not from pushing ever more units at the lowest possible price.

If we want to bring demand and supply into balance, several practical changes are needed on the brand side. First, reduce the number of styles and drops. Fewer, stronger styles with deeper size runs and planned replenishment reduce the need to overproduce. Second, extend product life by design. Choose fabrics and trims that stand up to washing, add repairability features, and avoid fragile finishes that fail fast. Third, use pricing and promotion responsibly. Permanent markdown culture teaches consumers to wait for discounts and pushes brands to make too much. Move toward clear, stable pricing with fewer promotions, and keep the sale section small. Fourth, invest in size accuracy and fit information. Better fit reduces returns, which are a large source of waste and emissions. Finally, offer after-sales services such as repair programs, spare parts, and alteration vouchers. These services help customers get more life out of each purchase and build trust with the brand.

Also Rea: When Will apparel Prices Really Start Rising?

Policy and market rules can support this shift. Extended Producer Responsibility (EPR) schemes that charge fees for products based on their durability and recyclability can discourage throwaway design. Bans or penalties on destruction of unsold goods reduce the incentive to over-order. Reduced taxes on repair services and second-hand sales can make it cheaper to maintain and reuse clothing. Transparent labels on durability and care can help consumers make better choices at the point of sale. None of these measures alone will solve the problem, but together they nudge the market away from ‘more and faster’ toward ‘enough and better.’

On the manufacturing side, the familiar steps to reduce overproduction remain essential. Tighter forecasting with customers, smaller batch sizes made economical through quick changeovers, disciplined marker efficiency, precise roll allocation, and digital approval workflows all cut waste before it starts. But manufacturers also need a new type of dialogue with brands about demand shaping. If brands show real sell-through data and share the learning from returns and customer feedback, factories can help redesign styles and assortments for longevity and accurate volumes. If brands commit to replenishment programs, factories can plan capacity more evenly and avoid speculative over-making. Contract terms should share responsibility for forecasting errors and cancellations so that no one party is pushed to carry all the risk. When risk is shared and data is open, the whole system becomes smarter and leaner.

A special note is needed about recycling. Recycling of pre-consumer scraps and post-consumer garments is important, and the technology is improving. But recycling uses energy and often downgrades material quality. We should treat it as a safety net, not a license to keep producing and buying too much. The first priority is to avoid making items that will not be used. The second is to keep each garment in use as long as possible through quality and repair. Only then should we recycle, what cannot be used further. This hierarchy—reduce, use longer, then recycle—protects resources for future generations and lowers the environmental footprint in the most efficient way.

The social benefits of right-sizing demand are clear. When orders reflect real need, factories can plan steadier work. This reduces overtime spikes and stress. It supports training schedules and skill development. It makes it easier to invest in safety and well-being because cash flow is more predictable. With fewer last-minute rushes and cancellations, relationships between buyers and suppliers improve. Disputes fall. Trust grows. Over time, productivity gains can translate into higher wages and better benefits in a sustainable way—funded by real efficiency and fair pricing rather than by squeezing margins.

Also Read: 5 Key Reasons Foreign Apparel Brands Choose Bangladesh for Sourcing

The economic benefits also add up. Brands that sell a higher share of units at full price keep more profit. They spend less on clearance and reverse logistics. They protect brand equity because customers associate them with reliable quality rather than with a permanent sale rack. Manufacturers that focus on quality, yield, and on-time accuracy improve their machine-hour economics and reduce rework. They can invest in automation and clean energy because their capital is not trapped in slow-moving stock or in disputes about cancelled orders. Banks and investors prefer these stable, transparent businesses. Insurance and compliance costs are easier to manage. In simple terms, fewer write-offs mean stronger cash.

For Bangladesh, the path forward is to link our well-known strengths in compliance and green factories with a reputation for precision and responsibility in demand. This means presenting ourselves not only as an efficient source of knitwear and other categories, but also as a partner that helps brands right-size their assortments. We can lead pilots on demand-driven replenishment, on durable basics with service guarantees, and on traceable waste-to-resource programs that are transparent and safe. We can showcase factories that have reduced fabric waste through better markers, cut returns by improving stitching quality, and stabilized lines by moving to smaller, more frequent orders. These are practical stories that buyers will understand and value.

Communication to the public should also change. The industry’s message cannot be only ‘buy sustainable.’ It should be ‘buy only what you need, buy better quality, care for it, and use it longer.’ This message may sound like it reduces sales, but it builds deeper loyalty and trust. Consumers who feel respected and well-served come back when they truly need something. They recommend the brand to others. They accept a fair price when they see honest quality and clear proof of responsible production. Over time, this trust is worth more than any short-term lift from a flash sale.

In conclusion, the RMG sector must solve two linked problems at the same time. We must stop overproducing in factories, and we must stop overstimulating demand in the market. If we keep only one promise and not the other, waste will continue. The practical way forward is to let fair pricing reflect real ESG costs, to design for durability and repair, to reduce the number of styles and promotions, and to share data so that forecasting improves. On the factory floor, we must tighten planning and execution so that every kilogram of fiber and every labor minute produces value that will be used. On the brand floor, we must respect consumers by offering fewer, better choices at honest prices. When we do both, the total volume of garments will shrink to the right size. Orders will match real need. Profit will come from value, not from volume. Workers will have safer, steadier jobs. The environment will carry a lighter load. And future generations will inherit an industry that is cleaner, fairer, and stronger than the one we grew up in.

About the Author

Sheikh Hossain Muhammad Mustafiz is a seasoned leader in the ready-made garment (RMG) industry, currently serving as Director of BGMEA (Bangladesh Garment Manufacturers & Exporters Association) and Managing Director of Cute Dress Industry Ltd. With deep expertise across garment manufacturing, sustainability, and industry policy, he is a strong advocate for more responsible and balanced apparel production.