For decades, turning U.S.-grown hemp into soft, textile‑grade fabric was simply impossible on American soil. Why? Because traditional degumming relied on harsh, oxidizing chemicals—processes incompatible with U.S. safety and environmental standards—which meant hemp had to be shipped overseas for processing. U.S. apparel brands thus remained stuck with imported or synthetic fibers despite growing domestic hemp cultivation.

Renaissance Fiber, a North Carolina-based company led by CEO Daniel Yohannes, has stepped in to solve the problem. Since the 2018 legalization of industrial hemp, the company’s key innovation has broken this bottleneck: a biomimetic, “Ecologically Invisible™” degumming process that transforms raw hemp into fiber as soft as cotton—without chemicals, without toxic effluent, and critically, compatible with existing cotton machinery.

Nature-Inspired Innovation

Renaissance Fiber’s method mimics tidal‑stream decomposition—where microbes gradually clean away non-cellulosic plant matter—allowing clean hemp fibers to emerge naturally. This eco‑inspired method avoids oxidizing agents such as peroxide or ozone and requires minimal water and no specialized infrastructure.

Also Read: What the H&M x Circulose deal tells us about leadership

It’s the first method to deliver spin‑ready hemp fiber that seamlessly drops into cotton mills—no new infrastructure, no adaptation needed, making scalable U.S. hemp textile production truly feasible.

Recognized and Scaling Fast

Winner—or finalist—of multiple awards, Renaissance Fiber was acknowledged as a finalist for the 2021 Ray of Hope Prize® from the Biomimicry Institute, celebrated for its nature‑based biotechnology and environmental impact. Judges praised the company’s system as regenerative, circular, and aligned with the ethos of biomimicry pioneers.

Other recognitions include the Venture Winston Grants and NCIDEA Seed grants for tourism and agricultural innovation.

In mid‑2025, Renaissance Fiber secured seed funding from Equilibrium Impact Ventures to build a refining facility in Mocksville, NC. This new infrastructure will enhance fiber fineness, length control, and compatibility with existing cotton-spinning systems—unlocking domestic scale for hemp textiles and supporting farmers, yarn mills, and brands alike.

The CEO’s Own Words

Daniel Yohannes captured the breakthrough in a recent LinkedIn post, “The conventional degumming process relies on harsh chemicals and methods that aren’t feasible under US environmental and safety laws. Since 2018 when industrial hemp was legalized this has been the bottleneck. So, we turned to nature for the answer. Our Ecologically Invisible™ process is a clean, biomimetic technology that creates fiber as soft as cotton, and was recognized by the Biomimicry Institute as such.”

Also Read: How Cellulose Fibres Are Shaping the Future of Sustainable Fashion

He added, “Most importantly, it’s the first process that creates soft hemp fiber, and with our refining process produces fiber that is spin‑ready and can drop into existing cotton machinery. No new infrastructure required for mills. This makes scaling domestic hemp production not just possible, but practical.”

“We couldn’t just stop at the fiber. We had to make it. This technology is what makes our all‑American hemp t‑shirt possible.

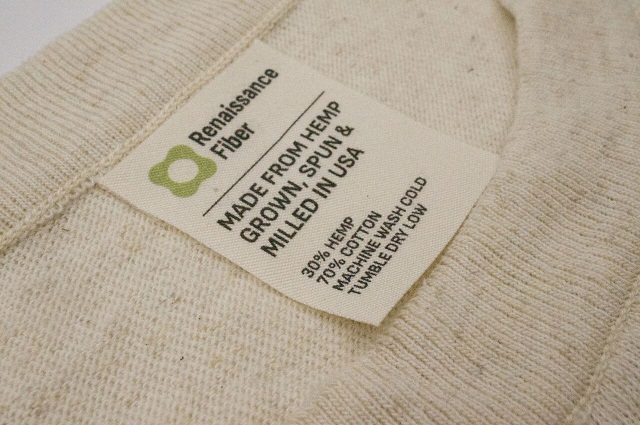

The proof here: see the innovation for yourself. Pre‑orders this first‑of‑its‑kind t‑shirt today.”

The Dirt-To-Shirt Comeback

In July 2025, Renaissance Fiber unveiled the first apparel‑quality U.S. hemp-blend t‑shirt fully made from U.S.-grown and processed hemp fiber. The product represents a first-of-its-kind realization: from domestic hemp harvest to consumer tee, made entirely on U.S. soil with fiber that can drop into legacy cotton yarn lines. Supporters describe it as a resilient, sustainable blueprint for American textile manufacturing .

Why It Matters

Environmental promise: Hemp uses less water than cotton and the company’s carbon-negative degumming sequesters carbon over geological timescales.

Supply chain resilience: Eliminating imports stabilizes sourcing, reduces vulnerabilities to tariffs, trade disputes, or climate disruptions.

Industrial compatibility: No novel hardware needed—fiber integrates with cotton mills already in place.

Scaling locally: The new Mocksville facility supports U.S. growers and yarn mills in building a transparent, traceable farm-to-textile pipeline

Looking Ahead

Renaissance Fiber is positioning itself as a trailblazer for a truly American hemp textile industry—one that harnesses clean tech, biomimicry, and regional agriculture to compete with conventional fibers. With early success in refining, fiber supply, and its inaugural U.S.-degummed hemp tee, the company is advancing toward broader applications in apparel, home textiles, and industrial fabrics.

If you’re a textile brand, retailer, or sustainability-focused investor, Renaissance Fiber offers a promising case study—and a tangible, scalable path to reimagining American apparel rooted in environmental integrity and supply-chain autonomy.