In the global race to develop new, high-performance fibers, from natural and regenerated cellulose to advanced synthetics, the journey from early laboratory ideas to commercial reality is fraught with hidden challenges. Engineers, researchers and manufacturers increasingly recognize that small-scale success does not guarantee performance at production scale. This has profound implications for costs, sustainability and time-to-market in industries ranging from textiles to composites.

This article synthesizes insights from recent industry thought leadership on the science and practice of fiber development, highlighting why scale matters, where common pitfalls lie, and how systematic pilot trials bridge the gap between concept and commercial viability.

Lab Scale: Small Samples, Big Insights

In early fiber research and development, laboratories routinely work with samples as small as 100 grams to test feasibility and performance. According to industry practitioners, a 100-gram fiber sample can yield meaningful performance data on key metrics, including basic fiber quality, yarn spinnability, and preliminary fabric behavior, without incurring the material waste or cost of full-scale production.

Also Read: Diversifying Beyond Oil: Azerbaijan’s Cotton Challenge

At this stage, researchers can measure essential fiber characteristics such as:

- Length, fineness and cohesion — which influence whether a fiber can spin successfully;

- Tensile strength and neps — indicators of mechanical behavior and processing quality;

- Comparative small-batch yarn and fabric tests — to gauge real-world performance analogues.

Lab equipment — including miniature spinning and knitting tools — enables rapid iteration by simulating larger processes in a controlled environment. The focus here is learning quickly and reducing risk prior to major resource investment.

LinkedIn

How Scale Shifts Fiber Dynamics

Even when laboratory results are promising, scale-related phenomena can dramatically alter fiber behavior once the material enters commercial machines. Recent discussions among fiber professionals underline that scale is not a simple matter of volume — it changes the physical environment around the fiber.

Thermal and Mechanical Forces Intensify

At the lab level, a small fiber mass heats and cools rapidly. However, in industrial batches, especially those exceeding thousands of kilograms, temperature gradients can develop within the bulk material. Those gradients can affect drying, fiber temper, and even lead to thermal degradation if not properly managed.

Similarly, mechanical forces escalate at higher throughputs. Larger, faster systems exert higher tensions and complex machine-to-machine interactions that can:

- increase fiber breakage;

- alter yarn uniformity;

- produce unexpected discontinuities;

- raise waste and reject rates.

Also Read: Weaving Human Rights Transformation for Sustainability

Moisture and System Interactions Become Production Drivers

Moisture, often treated as a minor lab parameter, becomes a production parameter, influencing static charge, friction, fiber strength, and process stability over long continuous runs. At scale, moisture cycling and ambient humidity shifts can trigger quality issues unseen in short lab tests.

Moreover, full production systems introduce airflow patterns, transport duct dynamics, and environmental controls that dramatically affect fiber behavior over hours of continuous operation — effects that a 100-gram sample could never simulate.

Lab Scale vs. Production Machines: Understanding the Hardware Gap

The distinctions between lab and commercial machines aren’t cosmetic — they stem from fundamental physics.

Smaller lab machines process low mass, leading to unstable tension and variable airflows that simply don’t mirror full-scale conditions. In contrast, commercial lines with heavy rollers and extended drafting zones generate consistent momentum, mass flow, and airflow patterns that stabilize fibers differently.

Because of these differences:

- lab systems are excellent for trend analysis, materials comparison, and mechanism studies;

- but they are poor predictors of absolute commercial performance metrics like uniformity, waste %, or large-run stability.

Recognizing each tool’s strengths helps teams interpret results more accurately and design better scale-up strategies.

A Five-Stage Framework for Fiber Scale-Up

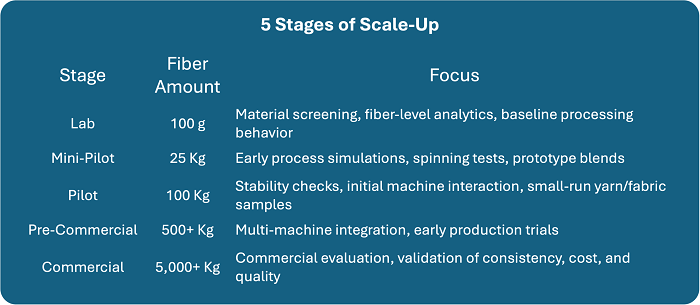

To avoid costly mistakes, industry leaders advocate for incremental scaling through mini pilot and pilot trials. They describe fiber commercialization as a five-stage scale-up process, with each phase serving a distinct purpose:

Lab stage (≈100 g):

Focused on material screening, fiber-level analytics, and establishing baseline processing behavior.

Mini Pilot Trials (25–50 kg)

Mini pilots use commercial machinery and settings to observe whether a fiber will even run at real speeds and through realistic equipment interactions. They help answer:

- Will the fiber feed smoothly?

- Does it clump or shed excessive waste?

- Do static and heat effects become problematic?

Because they mimic the mechanical and thermal environment of production, mini pilots reveal fundamental compatibility issues early.

Pilot Trials (100–200 kg)

Pilot trials extend the evaluation to consistency and stability over time. By allowing systems to settle-in and run continuously, these tests uncover issues that only appear during extended operation, such as:

- cumulative heat buildup;

- moisture and static cycling;

- quality drift during continuous runs.

Such trials don’t replace full commercial runs, but they significantly narrow the unknowns and guide process refinement.

Pre-commercial stage (500+ kg):

Involves multi-machine integration and early production trials, allowing manufacturers to assess system-level performance and scalability.

Commercial stage (5,000+ kg):

Dedicated to validating long-run consistency, cost structure, and quality before full market adoption.

Skipping steps, particularly the pilot stages, often leads to costly production failures, misinterpretation of lab results, and strained industry partnerships.

Why This Matters for Bangladesh

For Bangladesh, the world’s second-largest apparel exporter, these lessons are especially relevant. As the country expands beyond traditional cotton products into man-made fibers, recycled materials, and blended yarns, manufacturers face increasing scale-up risks.

Many Bangladeshi mills operate at high volumes with tight margins, where unproven fibers can disrupt efficiency, quality compliance, and buyer confidence. Structured pilot and pre-commercial trials offer a practical way to reduce risk, optimize machine settings, and meet the performance expectations of global brands.

As buyers push for sustainability, traceability, and innovation, the ability to scale new fibers reliably, not just test them in labs, is becoming a competitive necessity for Bangladesh’s textile and apparel sector.

Conclusion

In a world where materials innovation drives competitive advantage, understanding scale isn’t academic, it’s a business imperative. Technological advances in lab tools have made it possible to extract valuable insight from tiny samples, but true understanding of fiber behavior requires progressively larger trials, realistic machinery, and careful attention to systemic forces.

By integrating laboratory experimentation with scaled pilot evaluations, fiber innovators can unlock the full potential of new materials without the risk, waste or expense of premature commercialization.

(This article is based on and synthesizes insights from a series of technical commentaries by David McAlister, originally published on LinkedIn, drawing on his more than 40 years of industry experience across fiber manufacturing, research, product development and higher education, focused on solving complex challenges in fibers and textiles.